Sulbet®

Innovative chemical-resistant polymer concrete

Sulbet® is a chemical-resistant composite manufactured on the basis of the Sulstar® sulphur polymer and mineral or waste aggregates.

It has a resistance to corrosion in aggressive environments including i.a.:

- sea water,

- brine,

- effluent,

- concentrated acids

Its mechanical strength and lifetime exceed traditional concretes. The price is substantially lower than of other polymers.

Advantages

Savings resulting from the longer lifetime of products

Material savings due to 100% recycling

Durability and long lifetime of products

No costs related to servicing and installation – the products do not corrode and are not subject to the effects of adverse weather conditions, they do not become overgrown with algae, there is no need to paint them or to protect them with paints or varnishes

Ecological features of the solution – the technology does not require the use of water and the low energy consumption of the process results in the reduction of CO² emission

Shorter time of investment execution as there is no need to cure the material

Intended use

Application

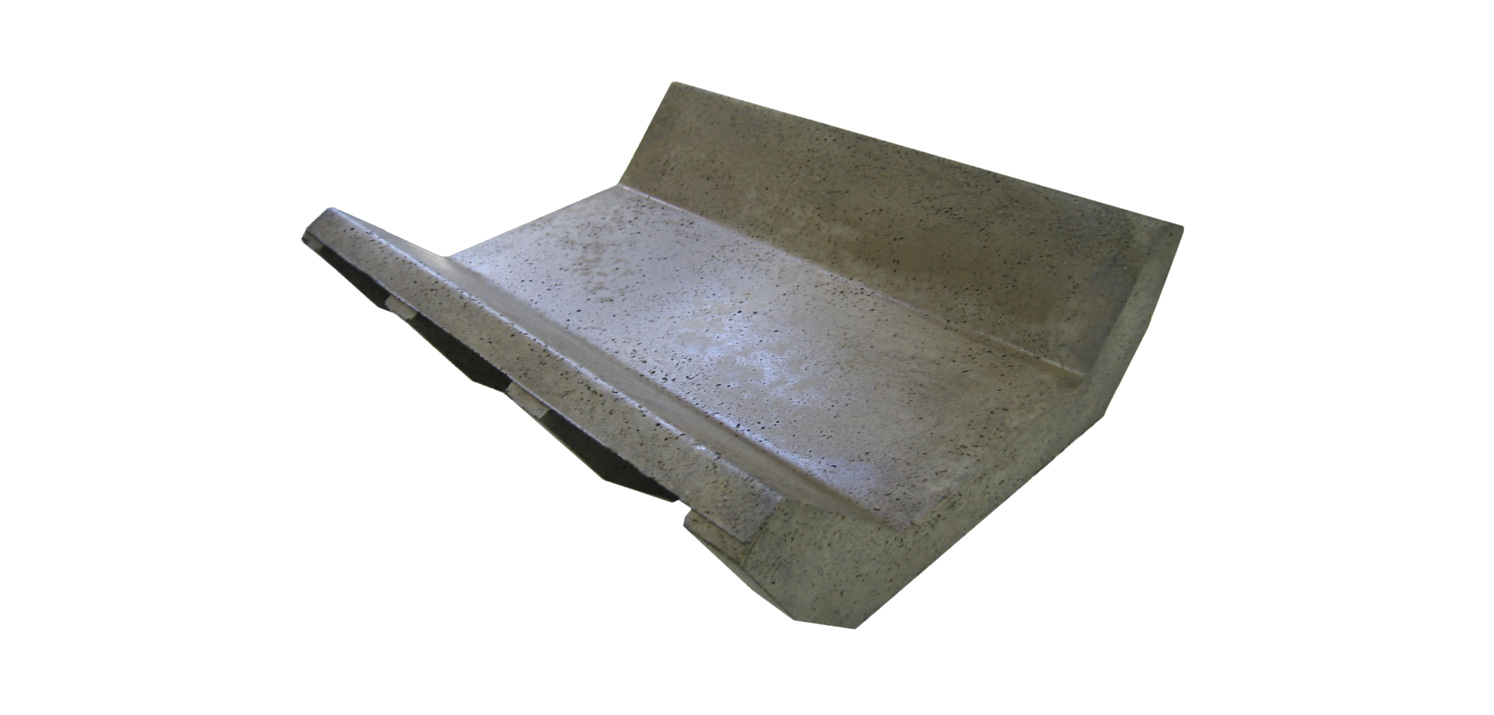

- kerbs, linear drainages, paving stones, catch basinsHigh modulus of elastic rigidity, high stability level according to Marshall, low sensitivity to the length of loading,

Properties significant for application

Compressive strength, resistance to corrosion, high frost resistance, long lifetime, chemical resistance, possibility of use a few hours after an element has been cast.

Application

- Weights tensioning railway traction networks, drainage channels of railway lines.

Properties significant for application

High density, compressive strength, resistance to corrosion, low absorbability, long lifetime, chemical resistance, possibility of use a few hours after an element has been cast.

Application

- Strengthening structures of sea and inland waters piers

Properties significant for application

Compressive strength, resistance to seawater, high frost resistance, long lifetime, possibility of use a few hours after an element has been cast.

Application

- Pipes, catch basins, sedimentation tanks, tank components

Properties significant for application

Compressive strength, resistance to corrosion, impenetrability, long lifetime, resistance to wastewater, possibility of use a few hours after an element has been cast.

Application

- Tanks, blocks for partition and retaining walls, slabs for landfills ground

Properties significant for application

Compressive strength, resistance to corrosion, impenetrability, long lifetime, chemical resistance, possibility of use a few hours after an element has been cast.

Application

- Grates for cattle and pigs, slurry, manure, tanks.

Properties significant for application

Compressive strength, resistance to sewage, resistance to corrosion, impermeability, long service life, possibility of use within a few hours after production.Technical data

Properties of Sulbet® polymer-concrete

| Properties | Obtained Values | Test performer |

|---|---|---|

| Compressive strength (depending on the applied aggregate) | 40 - 90 MPa | Construction Technology Institute, Silesian University of Technology |

| Frost resistance and salt resistance Test CDF (DIN CEN/TS 12390-9/B) | > F500 > 98 cykli | Barg Laboratorium Budowlane Spółka z o. o. (Barg Construction laboratory Co.) |

| Absorption | 0.1% - 0.05% | Construction Technology Institute, Silesian University of Technology |

| Crosswise resistivity | 2*1014 Ωcm | TPA Stuttgart, Silesian University of Technology |

| Teat transfer factor | 0.5 W/m*K | Barg Laboratorium Budowlane Spółka z o. o. (Barg Construction laboratory Co.) |

| Resistance to the effects of aggressive environments containing effluent and brine | Full | IZO ERG Zakład Tworzyw Sztucznych IZOLACJA COBR (Plastics Plant) |

| Recycling | 100% | Construction Technology Institute, Silesian University of Technology |

Contact

Aleksander Zwolski

e-mail: azwolski@marbetwil.pl

e-mail: azwolski@marbetwil.pl

- We offer a license for the application of the Sulbet® technology with know-how concerning the selection of aggregates, development of recipes, formation of products and manufacturing machines

- We ensure a constant supply of the SULSTAR® sulphur polymer

- We ensure cooperation in the scope of: testing and development, technical counselling, new product development and implementation

- • There is the possibility to begin manufacturing of particular products at our Manufacturing Plant in Gliwice, also under a customer’s brand

www.grupataka.pl

www.grupataka.pl