Store

Sulconcrete®

The answer to the question of copper and other non-ferrous metals’ post flotation wastes

Manufacturing technology of products based on wastes from the process of mining, and the processing of nonferrous metals and waste sulphur. The innovativeness of the process is related to the method of liquid waste sulphur polymerisation using post-flotation wastes and in its application as bonding for the production of sulphur concrete.

Ready concrete mass is formed into products applied in road, railroad, hydro-technical infrastructure and in construction. The possibility of granulating the sulphur concrete in order to transport it as a packed semi-finished product for large distances and execution of construction elements directly at a site represent global innovation. It provides new applications for sulphur concretes that have been unavailable until now.

Advantages

Technical data

Analysis of the technical and exploitation parameters of Sulconcrete®

| Properties of | Sulconcrete® | Traditional concrete |

|---|---|---|

| Flexural strength [MPa] | 100 - 15 | 6 - 7 |

| Frost resistance | F ≥ 500 | F 50 |

| Resistance to corrosion in an aggressive environment (sewage, sea water, acids) | Full | None |

| Tensile modulus [GPa] | 35 - 50 | 25 - 28 |

| Density [kg / dm³] | 2.2 - 3.9 | 2.4 |

| Time, after which an element obtains nominal strength. | A few hours | 28 days |

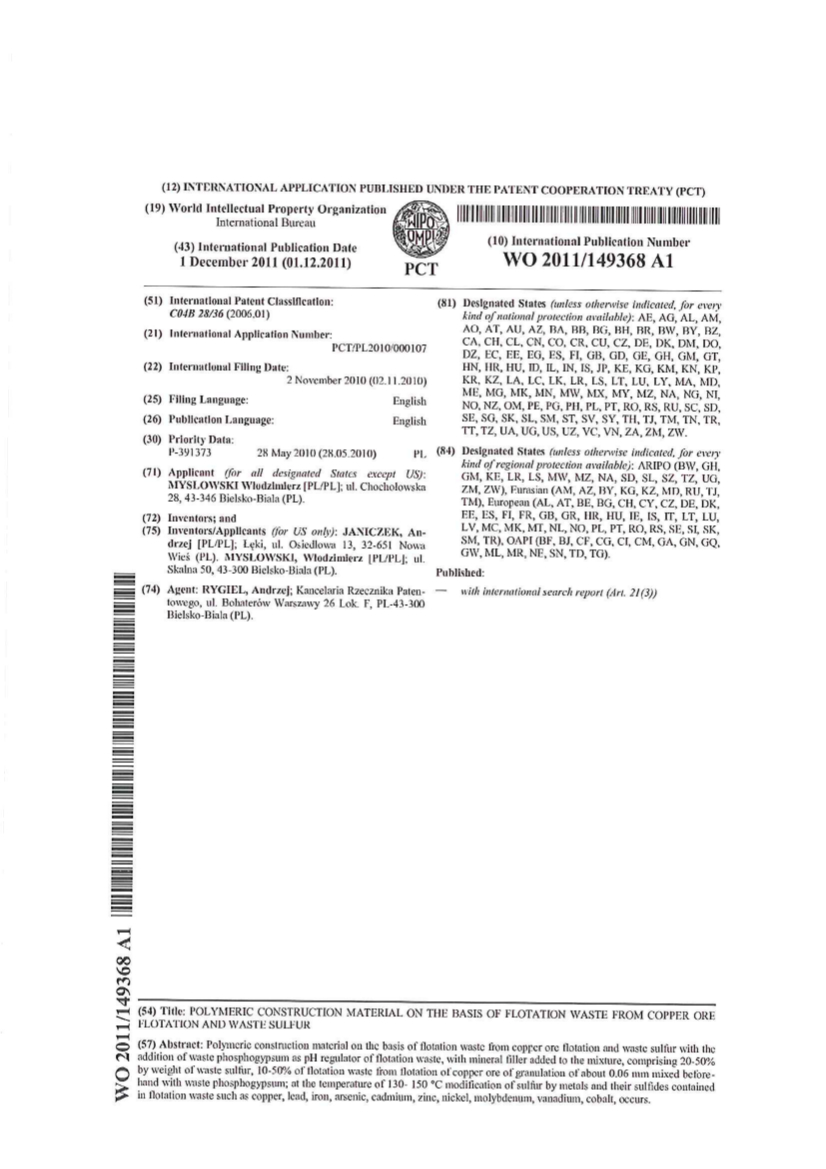

Patents

Patent

Nr 215185

Patent

Nr 215185 USA

Patent

Nr 215185 Mexico

Patent

EAPO

Notification

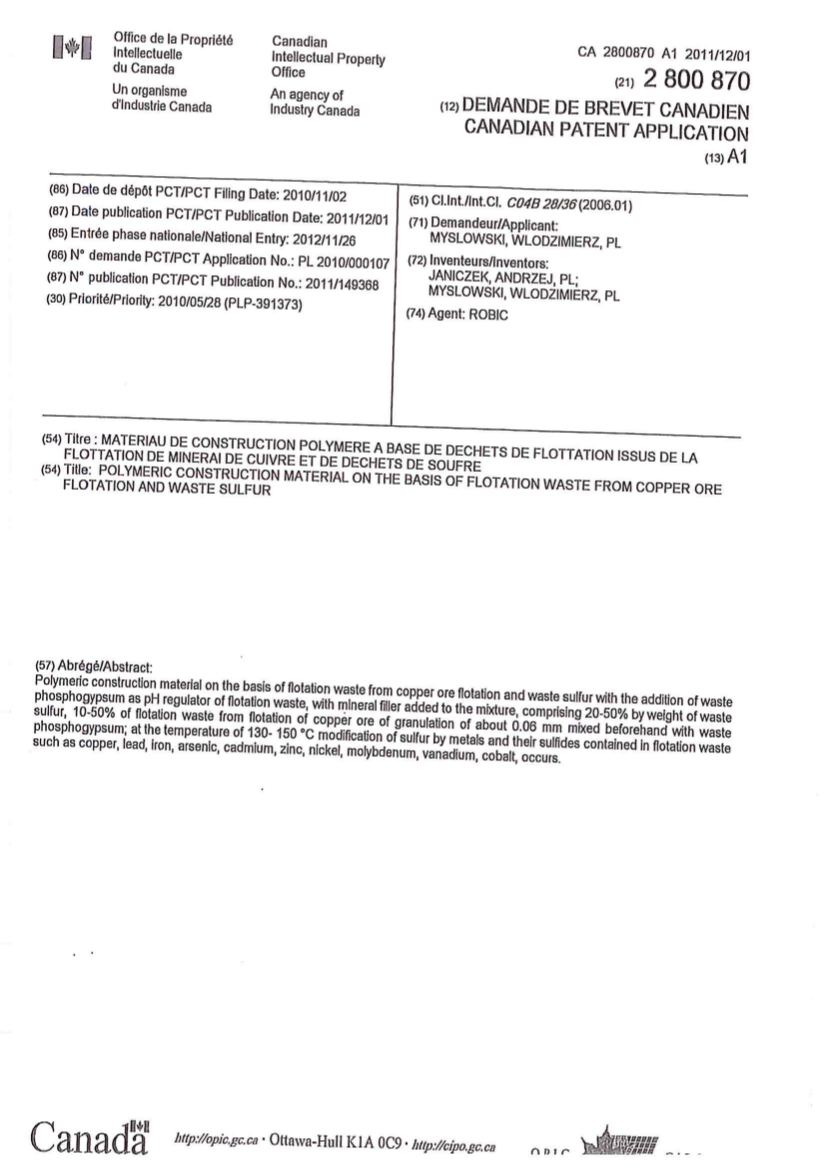

Kanada

Notification

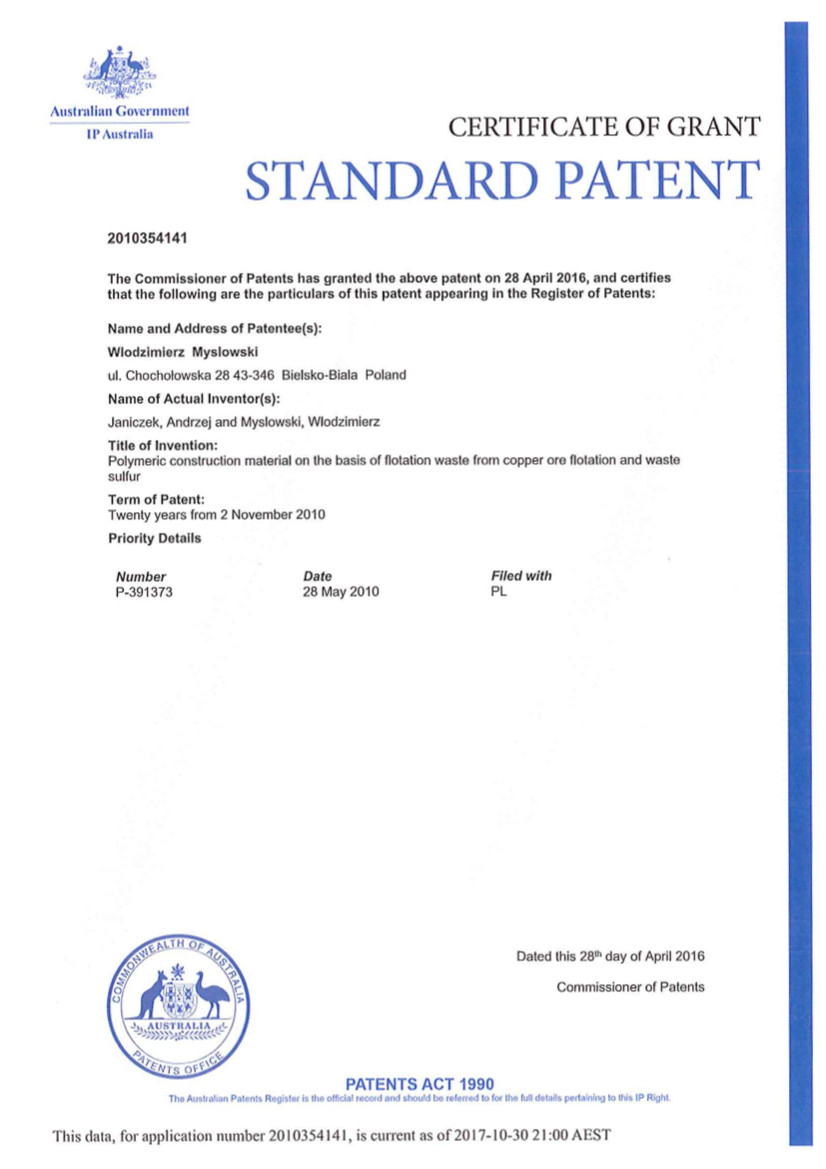

Australia

Patent

Australia

Patent

Contact

e-mail: mhiltawski@marbetwil.pl

www.grupataka.pl

www.grupataka.pl