Sulstar®

It is a new and unique technology of converting piles of waste sulphur into better harbours, roads and railroads.

We offer a proven, ecological and innovative solution to owners of large volumes of solid or liquid waste sulphur, solving their problems with the protection and maintenance of dumps.

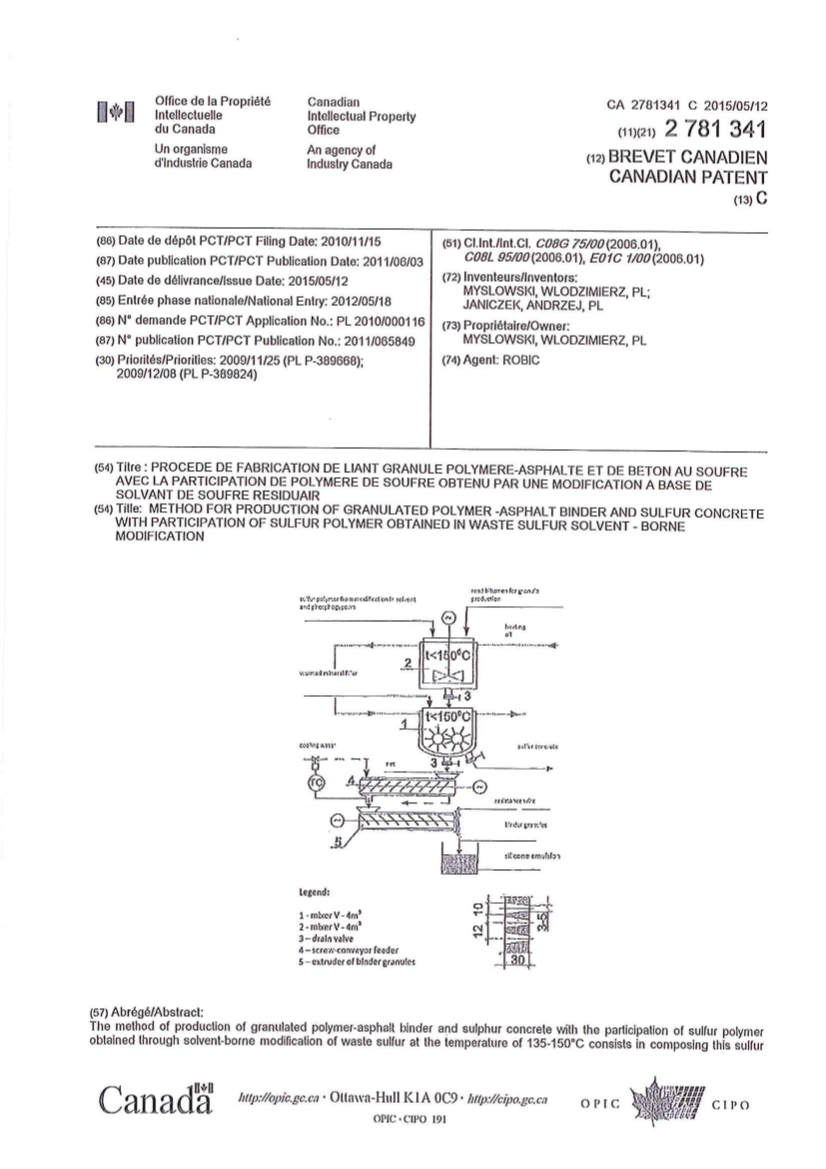

Contrary to the existing technical solutions, our authorial, patented modification method depends on running the process at presence of a solvent, which enables the substantial increase of process effectiveness and diminishes energy expenses, thereby lowering polymer costs.

POLIMER SULSTARcan be used for the stabilisation and solidification of industrial wastes, the result of which can be a prefabricated construction product (in the form of a kerb, dewatering trough, etc.) or granulated concrete, which can be stored in general conditions as a raw material for further production with no danger to the environment or people.

Advantages

Sulphur waste supplier

- elimination of costs and technical problems associated with waste sulphur storage

- freeing up of the area reserved for waste sulphur storage

SULSTAR

- polymer cost is lowered through larger output and the low energy consumption of the sulphur modification process

- the durability and long lifetime of products based on Sulstar, exceeds traditional construction materials by a few times

- lack of costs related to the cleaning of the products after installation, e.g. dewatering channels – our concrete does not become overgrown with algae

- the possibility of the sale or application of the product after 24 hours from manufacturing

Recipient of the processed raw material

- financial profit originating from the sale of ready products

- it is possible to completely 100% recycle the products

- converting waste into safe and useful products

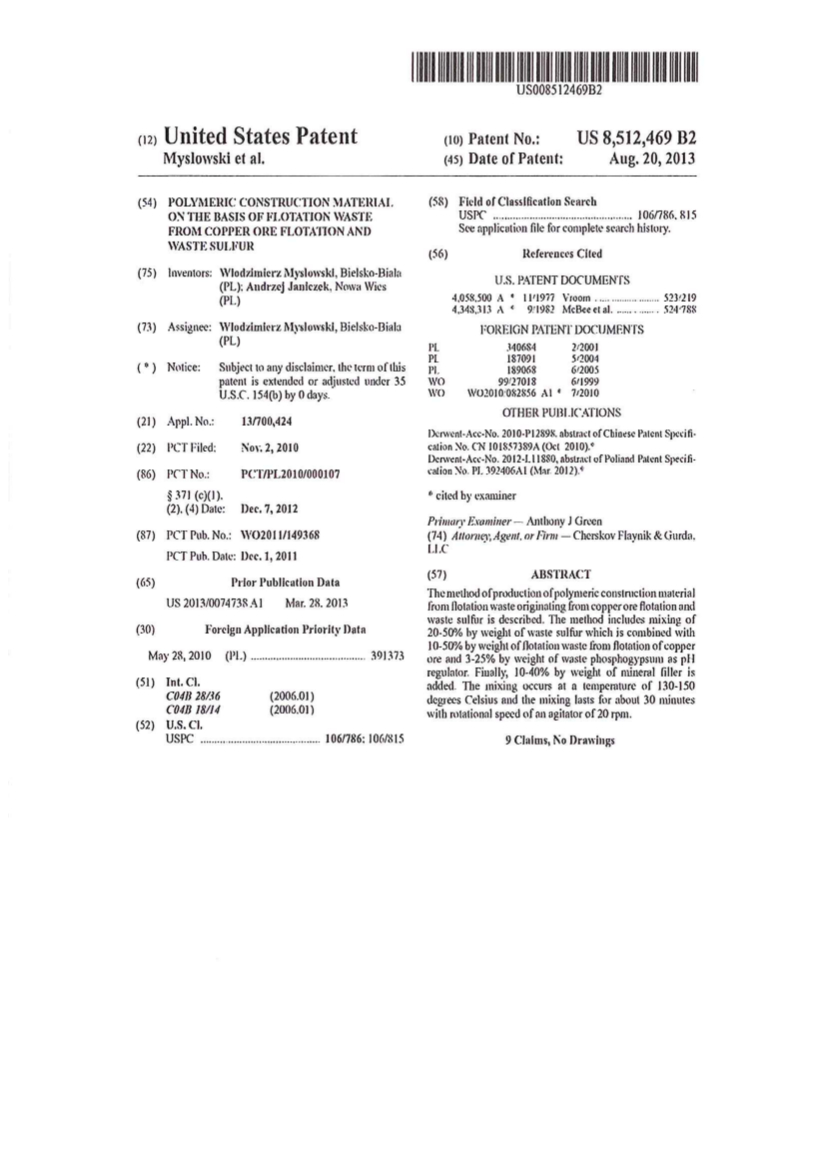

Patents

Sales of know-how

Marcin Hiltawski

Chairman of the Board

e-mail: marcin.hiltawski@marbetwil.com

Filip Mysłowski

Vice-President of the Board

e-mail: filip.myslowski@marbetwil.com

www.grupataka.pl

www.grupataka.pl